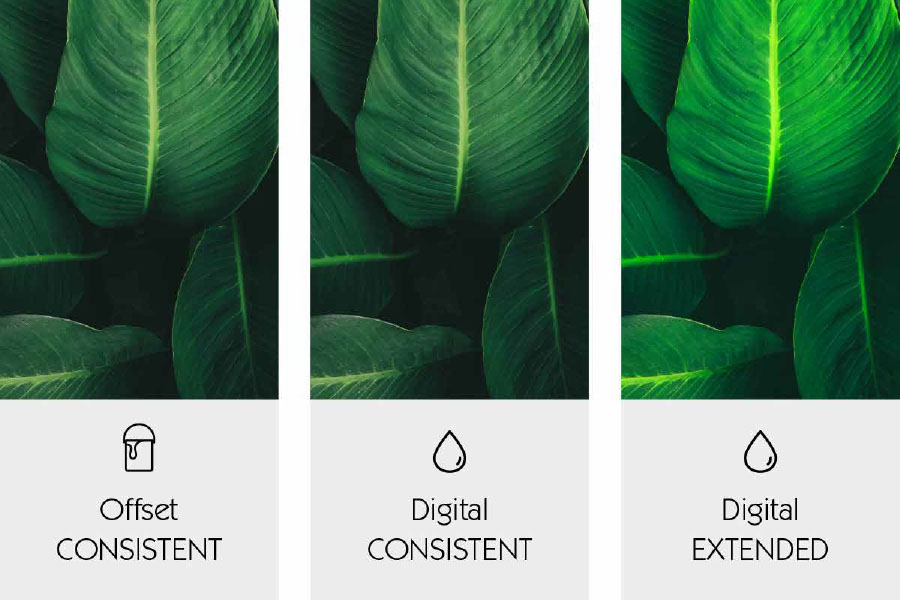

Consistent results — whether in digital printing or on a conventional printing press

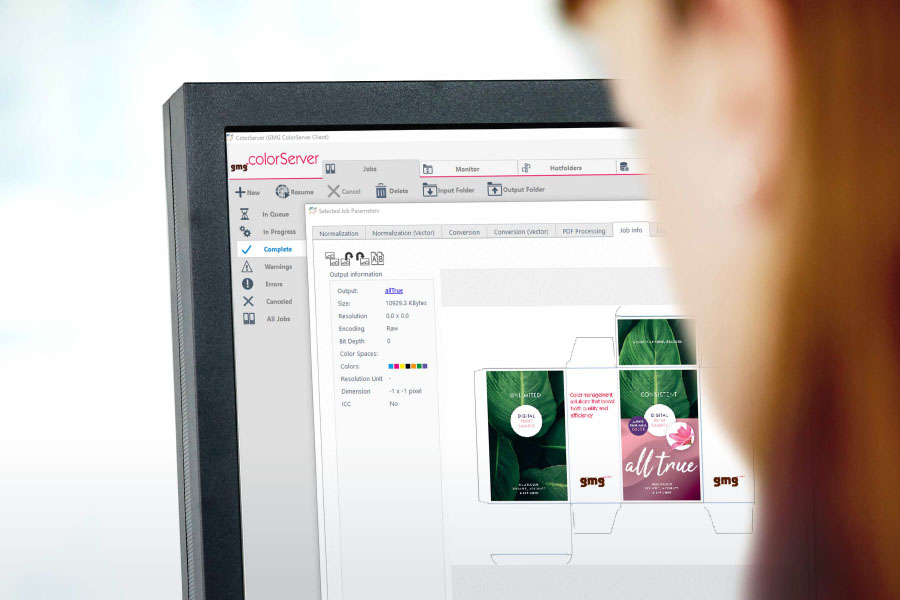

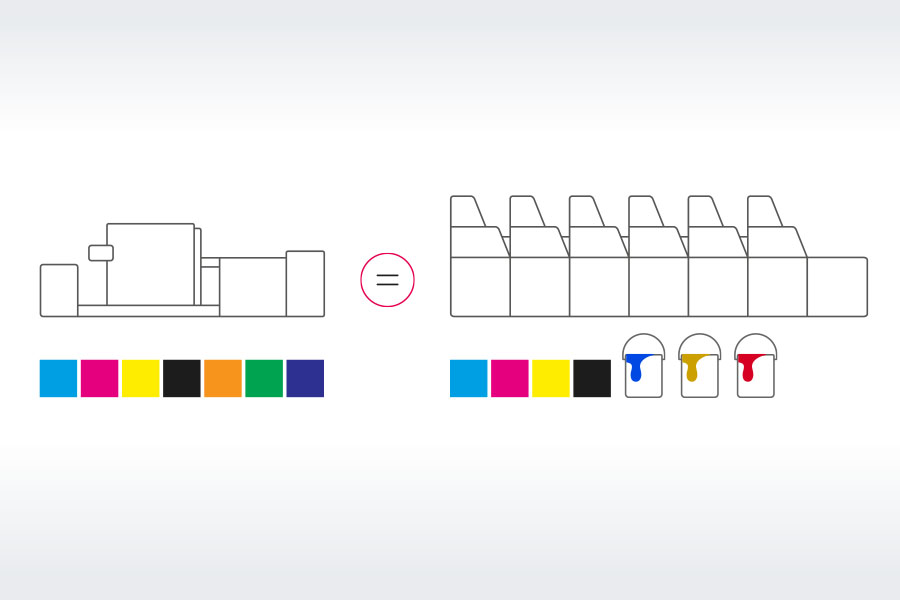

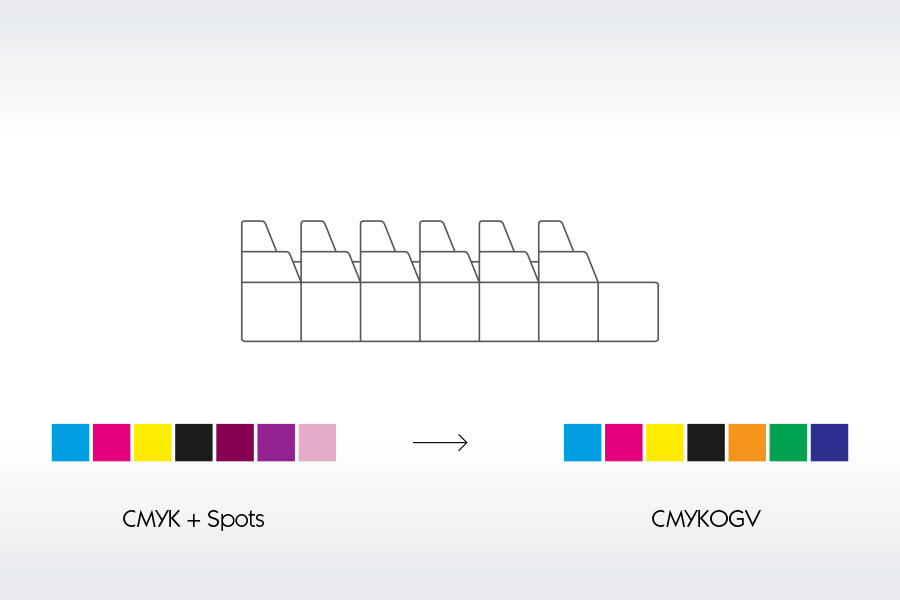

The packaging market is characterized by high demands on color reproduction. It is obvious that digital printing must look exactly like conventional printing. But how can this be achieved with a completely different printing process? With GMG ColorServer Multicolor, the exchange between the different methods is straightforward. The conversion instantly leads to consistent results thanks to the award-winning profile technology from GMG OpenColor.