Optimize Your Colors with GMG

With the GMG ColorServer GMG SmartProfiler solution, you gain the control to achieve reliable color consistency throughout your production chain, regardless of which press is used. By optimizing your print files, you will save both ink and clicks—all while printing with the highest possible color quality.

This video shows how you can create a hotfolder and calibrate your press using GMG SmartProfiler.

Several applications are required to optimize the entire process. In the following paragraphs, you will get an overview of each software element, its requirements and functions. The solution offers flexibility, allowing you to install all applications on the same computer or on separate machines. The applications communicate with each other via http within your company's network.

GMG ColorServer is the central PDF and image processing unit. All input documents will be processed by GMG ColorServer and the final PDF or image will be sent to an output folder. You can either connect the output folder to your Digital Front End (DFE) to run the system fully automatically or manually transfer the documents to the DFE. All color management including ink saving strategies will be done solely by GMG ColorServer. Therefore, it is necessary to switch off the color management in your DFE. If you are using a third-party workflow system, you can integrate GMG ColorServer into your workflow (see "Integrate GMG ColorServer into Workflow Systems").

GMG ColorServer is built using client-server architecture. The main Server will run on a central computer (or a virtual machine) in your local network. You can access the server from multiple connected clients, for example, to create jobs or to configure color management resources.

GMG SmartProfiler is the profiling tool of GMG ColorServer and helps you to stabilize and calibrate your digital presses quickly and easily. Some steps require printing and measuring of test charts. For this, you will need a spectrophotometer connected to the computer GMG SmartProfiler is running on. GMG SmartProfiler is included in the GMG ColorServer Client application. That means that you can run GMG SmartProfiler on a separate computer connected to the spectrophotometer. The resources generated by GMG SmartProfiler such as color profiles will be stored on the central server.

In the background, GMG OpenColor will serve as a profiling client. Based on spectral measurements, GMG OpenColor's prediction engine gets the most out of each specific printing substrate, ink set, and printing technology. GMG OpenColor will automatically generate the resources required to profile your press such as test charts and color profiles and send them to the central server. GMG OpenColor will also calculate a spot color library and send it to the central server before the jobs will be created. When you then process a job in GMG ColorServer, color channels from the document will then be processed with the color definitions from the spot color libraries. Resources created by GMG OpenColor will be synchronized, i.e. when you update a spot color library in GMG OpenColor, all dependent resources on the central Server will be synchronized automatically. With color management resources shared over the network, you will not need to switch between computers and manually transfer profiles anymore.

If you want to print a hardcopy proof, you will also need GMG ColorProof. GMG ColorProof uses the same profiling client as GMG ColorServer, i.e. GMG OpenColor, guaranteeing that the proof will match the print as closely as possible. Using a hardcopy proof as a reference for your digital printing process is highly recommended. Simply print a proof first and compare it with a reference print sample. If it matches, you can be sure that the characterization GMG OpenColor is using to calculate printer profiles represents the print results expected by you and your customers. After profiling your digital press, you can then compare the actual print results with the proof to close the loop.

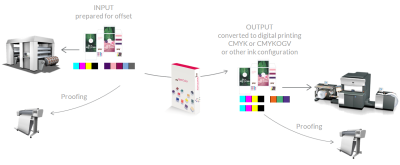

The illustration shows how the input documents are optimized for the target printing process. Input colors from the document are separated to the output inks of the target press. GMG ColorServer processes the input documents and applies the color management. In the background, GMG OpenColor delivers the conversion profiles and spot color libraries for the color management and thus plays a central role in this process.

After you have finished the initial installation and configuration of all applications, make sure the central GMG ColorServer server and GMG OpenColor are running. Then you can start the GMG ColorServer client and use GMG SmartProfiler to profile the printer and to create a hotfolder you can send the input documents to. In most cases, you will not need to configure anything else in GMG ColorServer or in GMG OpenColor at this point.