GMG OpenColor's prediction engine automatically calculates the best color match when separating spot colors for an all-to-CMYK-printing process. The resulting spot color library can now also be used in GMG ColorServer easily.

When preparing data for an all-to-CMYK printing process, you will need to separate all spot colors used in the original design to CMYK. GMG OpenColor's prediction engine automatically calculates the best color match for you. The resulting spot color library can easily be used in GMG ColorServer for an automated processing. Instead of manually tweaking spot colors in GMG SpotColor Editor, you can now simply export an already optimized library in db3 format directly from GMG OpenColor for use in GMG ColorServer.

You will be able to create separations for official print standards as well as in-house standards, including different printing substrates, ink sets, and printing processes. All you need is a fingerprint (characterization) of your target printing condition.

As the same database is used for proofing, an accurate proof-to-print match will be as easy and reliable as you can possibly think of.

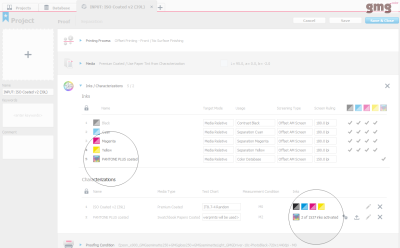

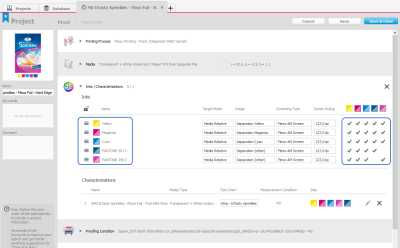

The input color space describing your document color space, for example, ISO Coated v2 (39L) + PANTONE PLUS coated, is defined by the Inks / Characterizations of an GMG OpenColor project. To manage your input colors, you can add or remove spot color libraries (pre-installed standard spot color libraries or your own custom libraries) from the GMG OpenColor database to the input project, and you can activate/deactivate spot colors that have already been added.

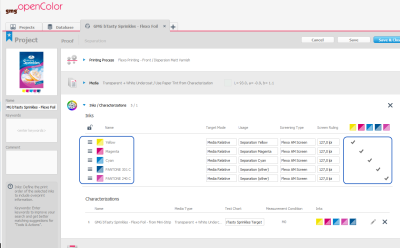

The preceding screenshot shows the Inks / Characterizations settings of the input project.

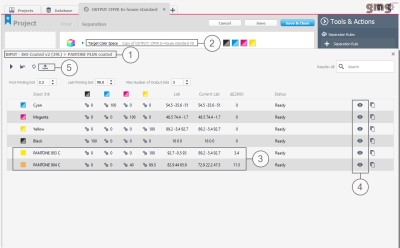

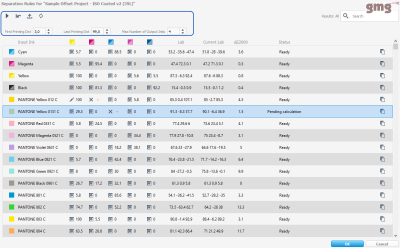

The output color space describing the target printing condition is then defined in a separate GMG OpenColorproject. For use with GMG ColorServer, make sure it uses only CMYK inks. To add a spot color library to your output project, click the Separation Rules button on the Tools & Actions pane and select your input project. The application will create so-called separation rules from the inks defined in the input project. The separation rules define how spot colors are separated from the input color space to the output color space. Of course, you can link as many input color spaces to the output project as you need. Just add more separation rules. To edit, view, or export existing separation rules, click the Edit button on the right side of the Separation Rules.

The preceding screenshot shows the Separation Rules dialog box, showing all spot colors as defined in the input project, ISO Coated v2 (39L) + PANTONE PLUS coated (1). You can see the output color space, a CMYK in-house standard (2), in the underlying main window.

The dialog box shows how the two spot colors PANTONE 803 C and PANTONE 804 C (3) will be separated to the in-house standard, including a delta E prediction.

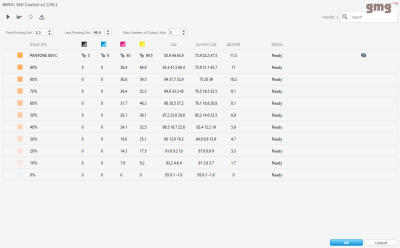

For a CMYK output color space, the GMG OpenColor prediction engine now calculates not only solid colors but tints as well. You can be assured that shades and gradients will be printed with the same quality as solid colors. You can show the tints by clicking the Show tints button (4).

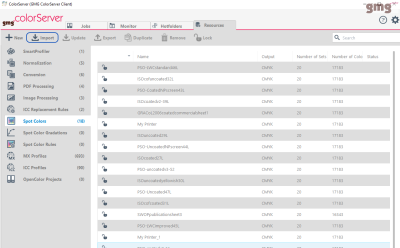

For use in GMG ColorServer, GMG OpenColor will now automatically create a spot color library from each Separation Rules list in db3 format. You can export the db3 file by clicking the Export button (5). You can then import the db3 as a resource in GMG ColorServer: Navigate to Spot Colors and click the Import button. Exported db3 files can be used in any GMG ColorServer version 5.0 or above.

Follow the link for further information on Creating Color Definitions.

With the additional OpenColor Separation license, you can now use all Printing Process types, i.e. Flexo, Gravure, and Offset, as input color spaces for separation profiles.

With this new feature, you can, for example, create an Offset-to-Flexo profile even if you have only a Flexo license. The other way around, Flexo-to-Offset profile, is not possible.

While extending the capabilities of the Separation option in this version, the license restrictions are now followed more strictly than in previous versions. You might experience not being able to use a project as output color space or as a proofing condition after the update, even if you have been able to do so before updating the application. Please contact your local sales partner or the GMG order team if you have further questions or if you want to purchase an additional license.

You will have full access to all characterization and separation capabilities so that you can define your input color space. However, if you want to use a project as an output color space or as a proofing condition, you will still need the corresponding license. This means, you can use a Flexo license to create an Offset-to-Flexo profile, but you will not be able to create a Flexo-to-Offset profile, separation rules, or proof profiles for a Flexo proofing condition without a Flexo license.

The processing time for smoothing measurement data has been reduced, especially for measurement data with more than 4 colors.

Follow the link to get more information on the spectral correction feature: Automatic Spectral Correction

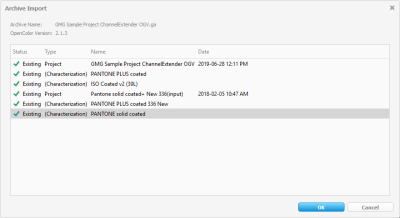

When importing data to GMG OpenColor from an archive, you will see an import overview, enhancing collaboration and preventing mistakes.

As an alternative to the Murray-Davies equation, this metric is now supported for the calculation and usage of gradation curves in GMG OpenColor.

So far, GMG OpenColor used the Murray-Davies equation, a traditional method to calculate tone values of CMYK inks from density measurements. Using this equation requires the use of manufacturer specific density filters. This leads to the SCTV standardization (ISO 20654:2017). The Murray-Davies equation is still available as an alternative option.

Switching the Calculation Method from Murray-Davies (MD) to Spot Color Tone Value (SCTV) in the Color Corrections dialog box is possible only if the spot color characterization includes tint values and if no correction has been applied so far. This means, if either a gradation curve was loaded as a correction curve or the calculated gradation curve was edited manually, the Calculation Method drop-down list will be disabled. This also means that if you are using a factory-default GMG spot color library such as PANTONE PLUS, the Calculation Method drop-down list will be disabled, as these libraries include only full tone values. However, you can load a custom gradation curve created with the Spot Color Tone Value (SCTV) calculation method to use the new method for these spot colors.

The maximum number of output inks has been increased from three to four.

Limit the number of output inks which can be a requirement for special packaging applications. Sometimes it might also be better to use less output inks and thus, compromise on the color for the sake of increasing the stability of the printing process.

Manually edit the output ink percentages.

Following changes in the project used as input color space, you can now update the range of available input colors and the target Lab values by clicking the Reload from Input Project button. Input colors that are not available anymore because they have been removed or deactivated in the project used as input color space will be removed from the Separation Rule list. New input colors will be added to the list. Changes to the target Lab values coming from changes applied to the Media or as a result of Color Corrections on the Project level will be applied. Your target values will be up-to-date and in line with the target values of the proof profile created from this project.

- For proofing multicolor prints without overprinting spots, it is now possible to export spot color libraries (in db3 file format) and import them into GMG ColorProof. This allows you to combine conventional MX4 profiles with spot color libraries from GMG OpenColor in GMG ColorProof.

Adding Spots That Are Not Used in Overprints - It is now possible to delete spot colors from a spot color library. GMG OpenColor's fail-safe and efficient change management takes care of dependencies.

- It is now possible to remove a gradation again after it was assigned to a spot color.

Creating a Spot Color Library

This improved behavior is applied automatically when a new profile is created. Already existing profiles will not be changed and not be marked as invalid when updating the application.

New behavior:

In this example, the two Pantone inks have swapped places. As you can see in the overprint overview on the right side, the overprint information is clearly reduced (fewer checkmarks indicating overprints), but not completely removed. Only overprint information of inks directly affected by the change will not be used.

Old behavior:

In previous versions, all overprint information was ignored, even information not affected by the change.

In recent years, investing more effort in improving the user experience of our products, we have learned to establish a culture and mindset that embraces user experience with lean-agile working methods adapted from the Lean Startup movement and Scaled Agile Framework.

Learning how our customers use our products really helps us to find patterns to improve the quality and fit of our offerings. To gather quantitative data, we collect anonymous usage information from within some of our applications such as GMG OpenColor from version 2.2.1 on. We do not collect any personal information or data from processed documents. If you do not wish to share this information with us, you can easily opt in and out at any time (Preferences dialog box > Service Settings > Allow Anonymous Usage Data).

You can find more information on this topic here:

You will get the highest possible profile quality, both for proof and separation profiles, even if the data quality is limited, for example, due to printer instabilities and noise or due to media characteristics. This feature eliminates the need for an external tool, saving investment costs and time. It also avoids a smoothing based on Lab values, thus providing an ideal basis for the GMG OpenColor prediction engine. Proof profiles will achieve a better print-to-proof match, so you might need less or even no optimization cycles when creating the profile.

This feature is available only for characterizations.

This is especially helpful if you have no access to the original data you imported into GMG OpenColor.

This feature is available only for characterizations.

If the option Hard Edge is selected, the curve steps directly from zero to the First Printing Dot as defined in the Printing Process, showing the characteristic hard edge of the printing process in the proof.

Keep Pure (No DE Limit) purifies all colors even if the resulting deviation from the characterization is high.

The Purify Colors option has been renamed to Keep Color Pure, but otherwise remains unchanged.

When the project configuration is changed by a user, the profile cache dynamically generated by requests from GMG ColorProof will be automatically cleaned up. For profiles created manually by a user, you can decide whether you want to keep them or not. If you keep them, they will be marked as outdated.

The change management regards changes to the Printing Process, Media, Inks, Color Corrections, or Characterization that will actually affect the profile. For example, when you apply a color correction to a specific output ink, only profiles using this output ink will be removed or marked as outdated.

Changes applied to the Noise, Missing Dot, and White Ink settings of the Proofing Condition and applied to the Ink Settings will always be ignored. This way, you can still keep multiple proof profile variants, for example, when playing around with the profile settings.

This feature is available only for proof profiles, not for separation profiles.

The application now recognizes relational information in the CxF file so that a spot color which might be characterized by a solid patch and tints of that color, for example Red 50%, Red 100%, will be imported correctly. GMG OpenColor will also read out printing process and media information from the CxF file. If the file contains information on multiple printing processes or media, GMG OpenColor will notify you, and you will be able to select the data you want to import.

Furthermore, this version supports the proofing of documents with embedded CxF/X-4 spectral data using GMG ColorProof version 5.10.1 or higher. GMG ColorProof automatically reads out spot color definitions from the document, which can be used in combination with a GMG OpenColor proof standard. The spectral data definitions are recalculated by taking the proofing condition into account. Please see the GMG ColorProof help or user manual for details.

- Epson ClearProof Film

- Epson ClearProof Thin Film

- Epson MetallicProof Film